Confidex Steelwave Micro II

PRODUCT DATASHEET

Small – sized asset tag with versatile attachment options and unparalled performance.

ELECTRICAL SPECIFICATION

Device type

Class 1 Generation 2 passive UHF RFID transponder

Air interface protocol

EPCGlobal Class1 Gen2 ISO 18000-6C

Operational frequency

Global 865 – 928 MHz

IC type

Impinj Monza 4QT

Impinj Monza 4E

Memory configuration

With Monza 4QT: EPC 128 bit; User 512 bit; TID 96 bit

With Monza 4E: EPC 496 bit; User 128 bit; TID 96 bit

EPC memory content

Unique number encoded as a default

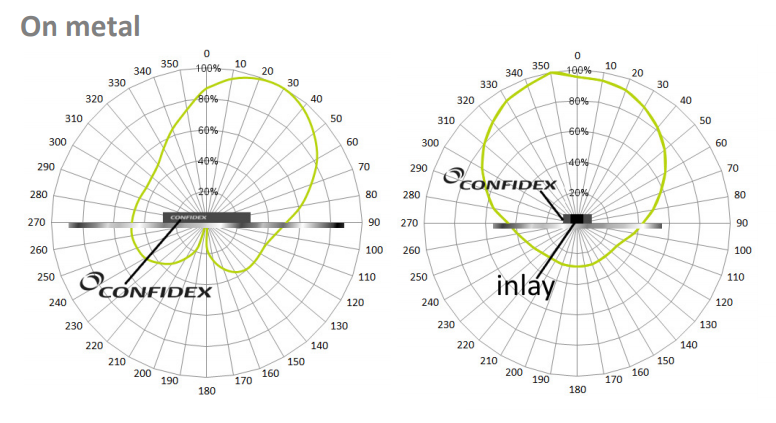

Read range (2W ERP)*

On metal up to 5 m / 16 ft

Off metal up to 1,5 m / 5 ft

Applicable surface materials*

Works on any material

* Read ranges are theoretical values that are calculated for non-reflective

environment. Different surface materials may have an effect on

performance.

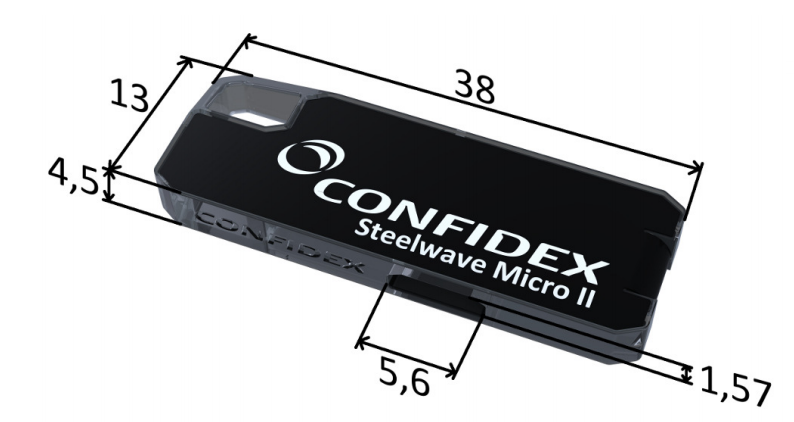

MECHANICAL SPECIFICATION

Tag materials

Engineering plastics and synthetic face layer

Background adhesive

High performance acrylic adhesive

Weight

2 g

Delivery format

Single

Amount in box

1000pcs

Dimensions

38 x 13 x 4,5 mm / 1.5 x 0.5 x 0.17 in

ENVIRONMENTAL RESISTANCE

Operating temperature

-20°C to +70°C / -4°F to +158°F

Ambient temperature

-20°C to +70°C /-41°F to +158°F

Chemical resistance

No physical or performance changes in:

-2 hour Salt water exposure (salinity 10%)

-2 hour Motor oil exposure

Additionally, short time exposure resistant against

sulfuric acid. Acetone and sodium hydroxide should be

avoided

Expected lifetime

Years in normal operating conditions

Environmental values are the best recommendations; resistance against

different conditions depends on the combination of all influencing factors,

exposure duration and chemical concentrations. Thus, product’s final

suitability for certain environmental conditions is recommended to be

tested.

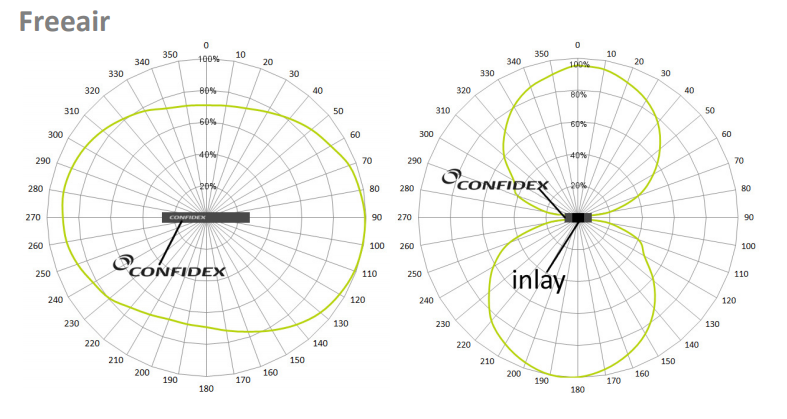

RADIATION PATTERNS

INSTALLATION INSTRUCTIONS

Steelwave Micro II can be attached with several fixing methods

High performance acrylic adhesive

Hanging with tethering string

Cable tie through the tag

To achieve the optimal performance in metal applications

please leave metal on the tag’s left side like shown in

image below. Ideally the tag is placed on large even metal

surface with direct metal contact underneath the whole

tag.

When mounting the tag with its adhesive background,

clean and dry the surface for obtaining the maximum bond strength

Ideal application temperature is from +21°C to +38°C

(+70°F to +100°F), bond strength can be improved with

firm application pressure and moderate heating from

+38°C to +54°C (+100°F to +130°F).

Installation at temperatures below 10°C (50°F) is not recommended.

ORDER INFORMATION

Zebra part number: 3000587

Product name: Confidex Steelwave Micro IITM M4QT

DISCLAIMER

THE MATERIALS, PRODUCTS AND SERVICES ARE SOLD SUBJECT TO ITS STANDARD CONDITIONS OF

SALE, WHICH ARE INCLUDED IN THE APPLICABLE DISTRIBUTOR OR OTHER SALES AGREEMENT.

ALTHOUGH ANY INFORMATION, RECOMMENDATIONS, OR ADVICE CONTAINED HEREIN IS GIVEN

IN GOOD FAITH, CONFIDEX MAKES NO WARRANTY OR GUARANTEE, EXPRESS OR IMPLIED, (i) THAT

THE RESULTS DESCRIBED HEREIN WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO

THE EFFECTIVENESS OR SAFETY OF ANY DESIGN INCORPORATING ITS PRODUCTS, MATERIALS,

SERVICES, RECOMMENDATIONS OR ADVICE. EXCEPT AS PROVIDED IN CONFIDEX STANDARD

CONDITIONS OF SALE, CONFIDEX AND ITS REPRESENTATIVES SHALL IN NO EVENT BE RESPONSIBLE

FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS OR SERVICES DESCRIBED

HEREIN.

Each user bears full responsibility for making its own determination as to the suitability of

Confidex products, materials, services, recommendations, or advice for its own particular use.

Each user must identify and perform all tests and analyses necessary to assure that its finished

systems incorporating Confidex products, materials, or services will be safe and suitable for use

under end-use conditions. Nothing in this or any other document, nor any oral recommendation

or advice, shall be deemed to alter, vary, supersede, or waive any provision of this Disclaimer,

unless any such modification is specifically agreed to in a writing signed by Confidex.